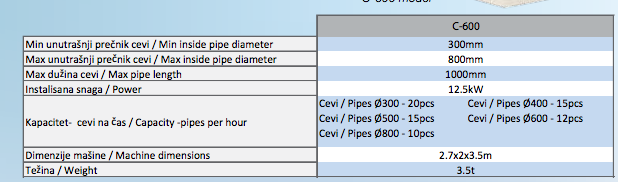

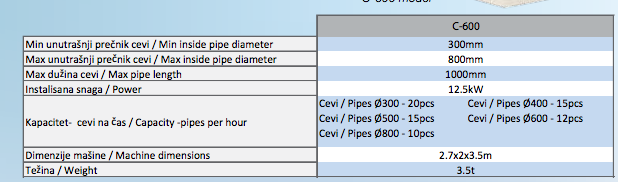

C-600 is machine for production of non-reinforced concrete pipes by principle of rotating head. Concrete is fed from upper side of mould. Pipe is transported together with mould to curing place, where is de-moulded and mould returned to machine.

C-600 is machine for production of non-reinforced concrete pipes by principle of rotating head. Concrete is fed from upper side of mould. Pipe is transported together with mould to curing place, where is de-moulded and mould returned to machine.

C-1200 METALIKA machine for concrete pipes combines low cost production, high output and simplicity into one outstanding package. With its new core vibration sistem, the C-1200 will produce pipe in numbers and compaction never-before achieved. Main feature: · High output · Semiautomatic · Extra rigid machine frame structure · Simple to use and maintenance · Strong vibrations Optional features: · Feeder for concrete · Automatic control unit · Accu driven cart for pipes · Modem link to Metalika technical service department.

Machines Concrete prices

Today modern machinery for the execution of concrete works is a substitute for human labor. They are made of high-quality components, according to the technical specification in various sizes.

The company Metallica is offering machines for concrete which are made by contemporary design, quality and functionality. With this machines for concrete, Metalika clients can perform construction work around the world.

Price usually depend on the type of machine and the type of concrete.

Concrete factory prices

Concrete Factories are high quality concrete products. Their advantage lies in mobility, easy to move around, to transport either on the truck or container and take little space on construction site. They can be installed in one day. Concrete plants can be automatic and semi-automatic. Price for concrete base or concrete plant is affordable, and they save lots on human labour.

Concrete mixers prices

Mixer is used for mixing and transportation of small quantities of concrete of liquid consistency. Besides being able to operate as an independent unit can be mounted on a truck carrying capacity 3.5 tons, or be towed as a trailer.

Vertical concrete mixers are ideal for the production of concrete mixers less humidity. Upper side serves to insert aggregates, and the bottom side has a door that opens to the emptying performed.

Thanks to high-quality sheet steel from which it is made drum mixers, the life time of dug. Adjusted shape and position of the blades inside the drum allows the production of excellent quality concrete.

Lines for wet cast concrete prices

Robotic production line for wet cast concrete are intended for the production of special concrete products. By using these machines for concrete involvement of the workforce has been reduced to a minimum which give you high productivity.

Production lines for wet cast concrete companies Metalika are very good quality and they are highly productive. Maximum safe for operators. Allow the production of different products in the same line.

The production process can be carried out automatically or semi-automatically.

Metalika- Mechanical machines for concrete prices

In this type of machine concrete vibrator includes machines for the production of masonry blocks. The machine is mobile and leaves the blocks after runaway. Filling and drop offs of concrete is performed classic trolley, while the dosing of the mold is by hand. Design of concrete elements in the mold thanks to the electromechanical vibration, which is attached to the mold.

Metallica – propelled machines for concrete prices

Self-propelled machines for concrete universal vibro machines intended for the production of concrete elements of all kinds. They have their own drive in all directions.

Metalika- stable machines for concrete prices

The stationary machines for concrete include: Block Splitter, Automatic line for relief cleaved concrete blocks, hydraulic machine that produces items on wooden or other surfaces. Highly productive stationary vibrating machine with disposal of final products.

Metallica – Set line price

Set line is an automatic machine for the production of concrete, with elevators, a return line for pallets and packing station for finished products.

Prices of machines for concrete works are formed depending on the type, size and type of machines. Please contact us for prices.

Prices mechanical machines for concrete Metalika

VP-4 is a mechanical vibrating machine for the production of masonry blocks

VP-4D is a mechanical vibrating machine for concrete masonry units. The machine is mobile and left blocks of the runway. Full is a classic stroller.

VP-5 is a mechanical vibrating machine for the production of building blocks, which leaves made items on the concrete surface. Capture of concrete to the machine is done by classical accessible and dosing of the mold manually. The elements are formed in a mold by vibration electromechanical attached to the mold. Machine manually pulls the runway and the elements remain behind.

VP – 5DSH the mobile vibrating press for producing building blocks and the like, which leaves made items on the concrete surface.

Prices of self propelling machine for concrete Metalika

SVP-12 – universal machine designed for the production of concrete elements of all kinds. It has its own power in all directions.

SVP-533- propelled, hydraulic universal vibro machine designed for the production of concrete elements of all kinds.

SVP-633 – Self-propelled, hydraulic universal vibro machine for production of concrete elements.

Prices stable machine for concrete – Metallica

block Splitter

S-610B is automatic line for relief cleaved concrete blocks.

VPS-1000 is stable hydraulic machine that produces items on wooden or other pads.

PS-2000 is a highly productive stationary vibrating machine with the disposal of finished products onto a wooden pallet.

VPS-3000 is a highly productive stationary vibrating machine with the disposal of finished products onto a wooden pallet.

VPS-4000 is a highly productive stationary vibrating machine with the disposal of finished products onto a wooden pallet.

VPS-5000 universal machine with the highest level of productivity. It is equipped Varioflex system synchronized and controlled vibration for maximum product quality.

Price Set line mixer Metalika

VPS-2000 -Automatic Concrete Stone machines with lifts, a line for the return of pallets and packing station for finished products.

VPS-3000 + SLP-12 production line of concrete VPS and Stacker range of SLP-12 charger.

Prices for concrete machines differ according to type of machine.

Concrete base Metalika

Construction of concrete equipment is very important for construction companies. With good quality concrete construction companies can get quality construction in a short period of time. By providing quality construction services to its customers in a short period of time, reduce labor costs and increase profits.

With the advancement of technology, today is a set of specific equipment for the concrete used in construction companies improve the construction process. Some of the basic and most important pieces of equipment for concrete is used widely in the production process in construction.

Production of concrete is much efficient , if used concrete plant.

Concrete factory

Concrete plants are made according to modern concept. They are simple and robust construction, with few moving parts, whose work is a reliable and cost-effective and have a long service life. They are used for the production of concrete on construction sites or in factories concrete component manufacturers.

After the capacity can be

-mini concrete plants

-Factory concrete, made for high-capacity production.

With the help of concrete plant, concrete which is used for construction is obtained by appropriate mixing of all the ingredients, such as sand, gravel, water and cement, and then the concrete is transferred to the site ready for use. The main advantage of using concrete plants is to reduce the inefficiencies and losses that occur during the production of concrete on building site. Factory can be stationary or mobile.

Stationary concrete plants are usually good for projects in which there is a need for a greater amount of concrete, but in only one place.

Mobile concrete plants are widely used in projects where there is a requirement to produce and transport concrete from city to city.

Factory mobile bases, are suitable for the production of all types of concrete, can be easily loaded onto a truck or in a container, take up little space, are installed in one day, can be automatic and semiautomatic.

Machines for concrete are useful for the execution of concrete structures, and therefore it is very important that they have a construction company.

The company offers quality Metalika made concrete base.

If you are looking for construction machinery concrete look at our wide range of machines on the site

Metallica products and other machines at a given technical documentation.

The successful placement of concrete depends on the careful mixing, appropriate equipment, and adequate transportation.

Dosing and mixing concrete

A concrete mixer is simply defined as the complete mixing of the material which is required for the production of a homogeneous concrete.

However, no successful mixture can not be achieved without proper dosing of the material. Quality assurance, convenient schedule of materials and equipment, and properly measure the materials are basic steps that must be completed before mixing begins to unfold.

Mixing components

There are many components to consider mixing to ensure to achieve high-quality concrete mixture. Location, shape and angle of the mixing blades, the shape of the mixing chamber, rotation speed, and horsepower must be taken into account. It is important that each group according to the specification consistently be mixed so that the final concrete strength is not compromised.

Classification mixer

There are three types of concrete mixer. These are the

drum mixer,

pan mixer,

and continuous mixer.

Further concrete mixers can be classifieds either dosed continuous free fall or forced movement, and stationary or portable.

Mixing time

When a suitable mixer chosen, it is necessary to determine the mixing time. It takes time to get mixed concrete when the mixer is fully loaded with all materials.

Mixing time is not standard for each mixer. For example, a drum mixer with a small diameter creates a greater speed than a mixer with a large diameter, therefore, the mixing time will be reduced.

Transport concrete

Transport concrete is defined as the transfer of concrete from the concrete mixing plant to the construction site. All concretes are still not mixed at the site, which is why it can sometimes require the transport of concrete. This usually refers to the ready-mixed concrete.

There are many elements of transport that should be considered to ensure that the concrete does not change its state. Two key objectives when transporting the concrete to the construction site to prevent segregation and to not reduce the workability of the mixture. The transportation process must be well thought out and effectively organized. As a general rule, thirty to sixty minutes of transport is acceptable for small jobs. In the central or portable ready mix concrete plants need to be released from the truck mixer or mixers on trucks within two hours. If the equipment is used for transport without interference, this time is reduced to one hour.

There are many factors that determine which type of service is most appropriate. Type and integral parts of the concrete, the size and type of construction, topography, weather conditions, location of the batch plant and the costs are taken into account when selecting modes of transport concrete. If you select the wrong mode of transport, it may be useless. Therefore, it is important to choose an adequate transport.

The machines for concrete works include:

– Concrete plants. These are machines and equipment for the production of concrete

– Concrete trucks, concrete pumps, tower cranes, are among the machines for concrete transportation.

– Vibrators pavers are the machines that are used for installation of the fresh concrete.

There are also machines and equipment for the manufacture, transport and assembly of products made from concrete elements and systems.

All of these machines for concrete works are distinguished by a number of operational and structural characteristics when performing concrete works in which participate.

Concrete plants are made according to the modern concept, simple construction, with few moving parts. With them is a reliable and economical operation of a life time is long.

They are used for the production of concrete on the construction site or in the factory of concrete semi-finished products. Mini concrete plants are suitable for the production of all types of concrete.

Because of their mobility is easily loaded on a truck or in a container, take up little space. Their installation is quick. They can be installed in one day, their price are going down to meet affordable level. They could be automatic and semi-automatic. They can execute any request, in a cost-effective production of good quality concrete.

Plate presses are used to produce building blocks, and similar products.

Inner vibrators used for compacting concrete. This is a great solution for concreting of large areas.

Machines for concrete elements can be automatic and semi-automatic and used for the production of all kinds of concrete elements.

Concrete mixers are used for mixing and preparing the masses for concrete industrial floors, providing a homogeneous mass and facilitation of obtaining the foreseen quantities of fresh concrete.

The external means of transport include:

Mixers, Dumpers

The two most automatic machines with are planetary mixer and forced-storage unit in a closed silo with partitions.

For transport of concrete pipe lines used pumps. The first pumps have appeared on the market in Germany as far back as 193 years. Today’s concrete pumps are special machines. A quarter of world concrete pumps installed today are concrete types pumps.

Metallica has for long time great production program. In addition to the production of equipment for concrete products, recently Metalika released to the market a new, fully automated production – robotic production line for the wet cast concrete.

All products line Metalike has, allow rapid production of regular, consistent quality, and rapid return on investment. Metalika company develops and offers the market a whole range of production lines for pouring wet concrete.

-CAROUSEL System for concrete products of maximum dimensions 500×500 mm, filling the mold, the product is suitable for the production of concrete blocks, paving slabs, concrete wall tile, concrete panel walls and fences and other minor concrete products.

-The Line filling of concrete products maximum dimensions 1000x2000mm product is suitable for the production of large concrete products, such as decorative wall panels, concrete floor tiles, sanitary ware, concrete tables and other concrete products.

– Robotic production line for special concrete products such as concrete elements for construction, concrete elements for industrial needs and concrete pumps with high output.

All of these production lines guarantee constant quality, high yield and optimum safety for operators, enabling the production of different types of items on the same line.

The production process can be automatic or semi-automatic. The production line support each stage of the production process.

-Mixers and concrete bases used for concrete

-Belt conveyors for concrete and other concrete trucks used to transport concrete to the site

– Flling concrete has a function as a unit for measuring and dosing of concrete, with automatic weight control.

-Robotic pliers are used for stacking and packing the mold and concrete products

-Transport products on the maturation of the concrete and the return of the room for maturing

Shelves and shelves-rail transportation system in the area where the concrete matures.

– Demoulding station, I removing from the moulds.

-Proces for oiling and cleaning the moulds.

-Automatic Weight control and optical control of dimensions and quality of products

Production lines operated by Metallica ranging from the simplest to the highly automated using very few manual labours.

Contemporary trends in construction coming into your country. Metalika adopt new technology of concrete and set new standards.

The concrete industry is slowly changing thanks to manufacturers and designers who are trying to create and identify new and better way of solving long-standing problems in the production of concrete. There are new products and approaches that will affect the production of concrete.

The construction industry is aimed at using innovation, the products are strong, durable construction that effectively use the material. There are new products and methods by which this objective will be achieved.

Thanks to the caring eye of endurance, concrete mix is changing and will change in many ways.

Concrete is considered a natural material, and create concrete is an artificial composite, part of which are binders, water, air and mineral aggregate – coarse and fine sand. Modern production of concrete means and adding chemical additives such as color pigments and reinforcing material.

Previously, the rule was that the key to high-quality concrete cement a certain amount or a certain ratio of cement and water. Today, the key to high-quality concrete is finding other methods that are energy efficient and environmentally friendly.

Pepo, blast furnace slag, metakaolin, pozzolana and other by-products of industrial processes give strength and other desirable characteristics of concrete mix with much lower energy consumption and carbon emissions in relation to production of concrete mixtures only portland cement.

The use of supplementary cementitious materials has already become a practice, and their beneficial effects ensure their continued role in the production of concrete.

In order to achieve the positive characteristics of concrete, are also participating, and various additives which improve the thermal properties of concrete, resistance to cracking and easier pouring concrete using concrete pumps. The additive into the concrete mix, concrete is more elastic, which helps to reduce the possibilities of cracking upon drying.

The products of the new generation of synthetic fibers for reinforcement of concrete mixtures help in achieving results that older versions of this material could not be achieved, because their effects were limited, because the fibers are used in high doses to prevent cracking of concrete, hard for mixing and pouring concrete .

New macrosynthetic fiber which appeared to have the characteristics that facilitate the process of mixing, discharging and design of concrete with the use of high doses of fiber. The new fibers are twisted shapes that prevents clotting, and also increases strength concrete mix, and allow for easier pouring and shaping concrete.

A large amount of synthetic fibers in the concrete slab, provides a certain level of elasticity, prevents cracking, while providing durable and solid surface, whic is is capable to withstand large loads.

To note that the use of fiber reinforcement reduces the use of labor. The most important benefit provided by the use of fiber is to improve the characteristics of concrete and its durability.

Construction machines are synonymous with technological development. Designing new model, and adapting existing ones to meet the quality requirements in terms of volume, speed and quality of construction work.

The use of machines for concrete works in the field of construction is imminent, indeed there are examples of the construction machine is constructed and produced for a predetermined construction work or object. Machinery in this part of the construction industry is very active, especially in the production of small construction machinery. Therefore, we frequently see new machines in the market.

In the construction equipment Concrete include all kinds of typical machines, special construction funds, technological equipment and machines for concrete structures.

Metalika Sopot manufacture concrete machines for processing concrete, self-propelled vibratory presses, highly productive, stable presses for the production of blocks, curbs, behaton , grid, Mixer different size and mini-planetary mixer concrete plant, lines for billets, Straighteners for concrete, mechanical presses for concrete crusher brick and stone, rebar bender …

We offer the following special machinery concrete:

– Fixed Concrete Stone machines

– Mobile and stationary machines for concrete blocks

– Plants for concrete blocks and Stone on a “turnkey”

– Molds for concrete elements for blocks, behaton curb/plates, flower pots, parking grids, chimneys …)

– Presses and lines of cleavage blocks of stone and concrete

– Machines for concrete pipes C-600 is a machine for the production of non-reinforced concrete pipes principle of rotary heads

– Concrete mixers of various sizes (M-250 / M-500 / M-750 / M-375 / M-1000)

The concrete base:

Purpose of the concrete base is to produce high quality and quantity of concrete in a relatively small device, which is achieved with continuous adding and mixing aggregates, cement, water and additives in the desired relationship. The main parts are: hoppers with strap unit, mixer and dispenser for cement. Produced concrete is discharged from the mixer directly on the conveyor belt or conveyor basket. Continuous dosing of aggregates and cement is done by regulating the number of revolutions per minute conveyor. Continuous dosing of water and additives is carried out by regulating the pressure and flow. Dispenser consists of cement screw conveyor with hopper and rotary valve positioned above the mixer. Supply of cement silos can be made in “big bag”, or “hopper” with the capacity of 500kg.

Automatic concrete bases are of medium capacity and an extremely favorable price:

Machines for processing of reinforcing steel which includes Straighteners (Automatic line for straightening and cutting reinforcing steel), Benders (hydraulic machines for bending and cutting reinforcing steel, and knives.

– Silos for concrete

– Circular saw blades for wood and stone

– Mills of stone, brick rubble and glass

All these machines Concrete differences among the numerous operational and structural characteristics, followed by their mobility, according to special technological procedures and operations of concrete works in which they participate.

Metalika strives to provide its customers with the best possible service throughout a range of equipment and complete technical support after the sale.

All products are distinguished high quality Metallic in terms of design and functionality, which are adapted to the conditions in the building industry around world. As a proof, there are numerous references that used Metalika products in buildings worldwide: Like Russia, Sweden, Polish, Georgia, Romania, Bulgaria, the countries of former Yugoslavia, Libya, Morocco, Egypt, Ghana, Guinea, Tanzania, Angola.

The heavy concrete machinery is a critical tool for construction activities and they are such integral part of the overall construction process in any construction project. So manny construction projects are almost impossible without using the heavy concrete machines .

The improvement and development of Concrete machinery replaced a lot human labor, increased productivity and ensured safety at work. For decades, these machines have proved to be the ideal solution for construction companies that want to have quality and efficiency at the same during construction works. In effect, an innovation involving new technology and method led to considerable cost and time savings.

Thanks to modern concrete machines man is released from inhumane and heavy work, such as work by cold, rain, cold weather, mud, water and the like.

Application of concrete machines requires a thorough knowledge of their capabilities, as well as knowledge of the areas in which the work is performed: the type of work and technology that is applied in the work.

Recent development and progress of industrial production made the products strong, precise and economical that meets the demands of work and technology. Although the development of construction started by using ropes, wheels and levers but in near future they will be presented with electronics, satellite, remote control, vending machines and robots.

The demand for use of machines in almost all segments of the construction industry has recently increased. Therefore, the concrete machinery manufacturers are forced to produce practical and efficient machines applying technical innovations. Procurement of concrete machinery should be approached studiously, in order to choose the most suitable type for the needs of certain construction work.

The selection of the appropriate type and size of construction equipments often affects the required amount of time and effort and thus the job-site productivity of a project. It is therefore important for site managers and construction planners to be familiar with the characteristics of the major types of equipment most commonly used in construction.